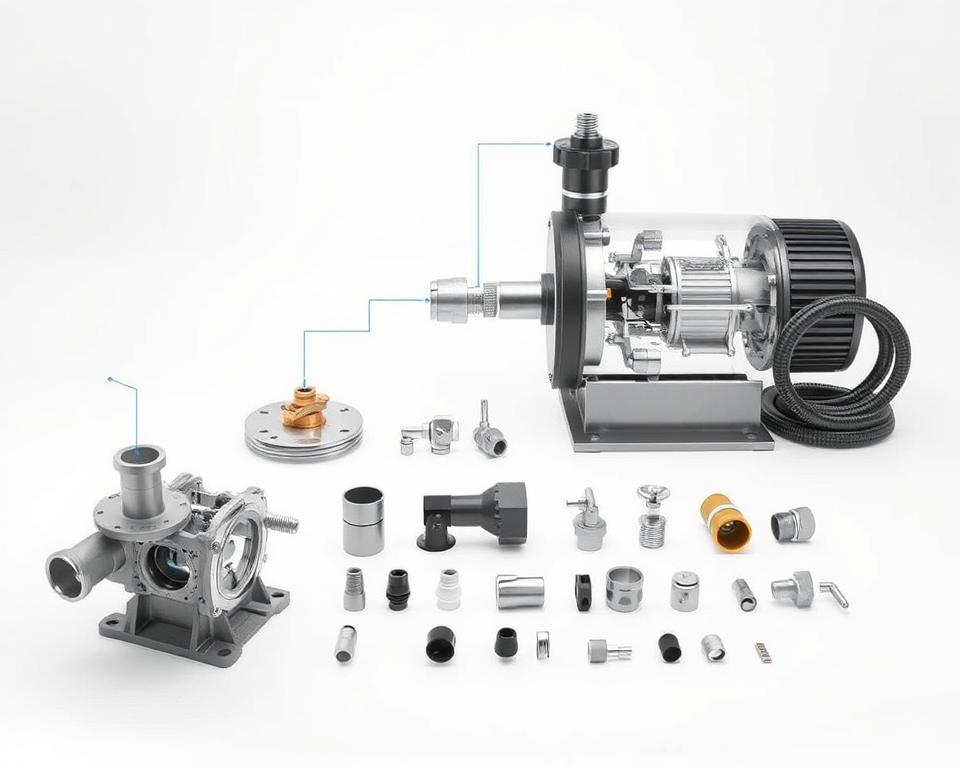

Shurflo Liquid Pump Diagram – Installation Components Supply

Faulty installation of liquid pumping devices can significantly diminish their efficiency by up to 30%. It’s essential to comprehend the operation of the Shurflo Water Pump schematic for optimal operation and longevity. Each component within the diagram plays a crucial role in the operation of the Pump. We will explore the importance of understanding these Shurflo fittings, employing the schematic to demonstrate their assembly and how they function collectively.

Parts Supply for Installations is your preferred provider for every Shurflo Pump component needed for installation and upkeep. Gaining knowledge from the Shurflo Pump parts diagram empowers users to proficiently manage installation and upkeep. This knowledge helps in forming informed choices for the effective and safe operation of their water pumps.

Comprehending Shurflo Pump Systems

Shurflo Water Pumps are at the intersection of ingenuity and functionality, satisfying the needs of multiple functions. This portion strives to offer a comprehensive view of Shurflo Pump models, their specific uses, and the advantages of selecting these Pump systems. They are renowned for their advanced technology and performance.

Summary of Shurflo Pump Models

Shurflo’s assortment features Pump models like the membrane and farm series, crafted for varied demands. The membrane models are acclaimed for their sturdy design and efficiency in moving liquids. Models like the 2088-343-135 and 2088-343-500 offer robust performance with notable flow and pressure capabilities.

The horticultural series, conversely, is built for optimal fluid conveyance in greenhouse applications.

Uses of Shurflo Pumps

The flexibility of Shurflo Pump systems enables their use in a range of settings. They are commonly used for:

- Agriculture: Offers methods for watering and nutrient application.

- RVs: Maintains a steady water flow with controlled pressure.

- Residential: Well-suited for landscaping and home fluid systems.

This flexibility enables these Pump systems to blend seamlessly with different systems, demonstrating their multifunctionality.

Advantages of Choosing Shurflo Pumps

Selecting Shurflo Pump systems offers several benefits. Their automatic priming function removes the hassle of manual priming. They also possess resilience to chemicals, ensuring longevity in harsh environments. Readily available Shurflo diaphragm Pump parts simplifies maintenance, boosting service life while reducing idle periods. Further advantages of Shurflo Pumps include:

- Stable performance that can be customized with adjustable pressures.

- Simple setup aided by an extensive parts catalog.

- Various connection options for smooth system integration.

With these features, Shurflo Pumps ensure efficiency and reliability. They guarantee ongoing functionality, assuring users of reliable operation.

Shurflo Water Pump Diagram and Its Importance

The Shurflo Water Pump diagram is critical for understanding its components and functions. By learning about the Shurflo Water Pump schematic, users can put together, troubleshoot, and preserve optimal performance. This schematic is vital for locating the needed Shurflo Pump parts. Correct configuration ensured through the schematic guarantees peak performance.

Key Components in the Diagram

The Shurflo Water Pump assembly diagram showcases critical elements necessary for proper operation:

- Engine: The engine, the pump’s core, powers the impeller, delivering flow rates between 41 and 168 GPM.

- Membrane: Helps sustain uniform flow and pressure.

- One-Way Valves: Essential for blocking reverse flow, these valves guarantee that water moves correctly.

- Housing: With a maximum pressure of 200 PSI, the casing ensures durability.

Interpreting the Shurflo Pump Schematic

To interpret the Shurflo Water Pump diagram, one must pay attention to distinct symbols and markings:

- Study the layout of parts shown in the schematic.

- Determine the movement direction marked by arrows.

- Check notes for details like wire sizes and mounting options.

Mastering this diagram is essential for proper assembly, maintenance, and identifying key components.

Setting Up Shurflo Water Pumps

Setting up a Shurflo Water Pump can enhance the functionality of any liquid system. Knowing the necessary steps and components is vital for a proper assembly. This guide covers vital steps and the tools needed for a successful setup.

Installation Procedure for a Shurflo Pump

- Begin by gathering all tools for shurflo pump installation. Make sure you have items like a suitable screwdriver, wrench, and 50-mesh strainer.

- Attach the 50-mesh strainer to the inlet of the Pump. Preferably, use a pliant hose for connecting the inlet to minimize strain on fittings.

- Use a 1/2” to 3/8” barb splicer for securing tubing connections. To deter leaks, select reinforced tubing with Oetiker clamps.

- The pump should be wired to a properly grounded outlet. A licensed electrician must perform this to meet regional standards.

- Pressurize the accumulator tank to 50 PSI with filtered air or nitrogen. This is vital for achieving ideal pressure levels.

- Install a SHURflo 65 psi valve to lower water pressure at the inlet to ensure correct operating pressure.

- Wrap up the setup by connecting all components. Avoid overloading the motor’s amperage; incorporate thermal breakers for additional safety.

- Test the system and check the pressure switch’s functionality.

Necessary Equipment and Components for Setup

| Component | Details |

|---|---|

| 50-mesh filter | Removes contaminants at the inlet for superior operation. |

| Pliable hose | Recommended for inlet connections, reduces strain on fittings. |

| Barb splicer | 1/2” to 3/8” connection for secure tubing attachment. |

| Storage tank | Charged to 50 PSI to ensure stable operation. |

| Switch | Manages Pump function according to pressure needs. |

| Electrical equipment | Required for safe connections, ensure compliance with local electrical codes. |

| SHURflo 65 psi valve | Reduces water pressure entering the pump for consistent operation. |

Troubleshooting Common Issues with Shurflo Pumps

Understanding how to remedy frequent problems in Shurflo Pump systems enhances performance. This segment offers a troubleshooting guide. It helps users diagnose and resolve frequent problems to secure continuous performance. Troubles such as non-operation, poor flow, and excess noise are resolved using practical methods.

Typical Issues and Remedies

Varying scenarios lead to issues with Shurflo pumps. Below are key problems and their solutions:

- Pump runs but no water flow: Check the freshwater tank level, inspect the water line for blockages or damage, ensure proper priming, and verify the water pump’s functionality.

- Pump fails to start post-winterization: Revisit correct winterizing steps, check that valves remain open, confirm wiring integrity, and look for any component damage.

- Pump cycling on and off: Examine the system for leakages, purge air pockets, set correct pressure levels, and confirm Pump operation.

- Noisy pump: Check for unsecured fittings, incorporate vibration dampening, insulate piping, and verify correct mounting.

Shurflo Pump Troubleshooting Guide

A complete Shurflo Water Pump troubleshooting guide aids in swift diagnosis. Presented here is a table outlining frequent faults and their remedies:

| Common Issue | Possible Reasons | Remedies |

|---|---|---|

| Pump runs but no water flow | Low freshwater tank, blockages, improper priming | Examine reservoir, review piping, confirm Pump operation |

| Pump won’t turn on | Faulty winterization, sealed valves, power connection problems | Reassess winter steps, ensure valves are open, verify wiring |

| Pump cycles on and off | System leakages, trapped air, incorrect pressure settings | Examine for leakages, eliminate air, modify pressure controls |

| Excessively loud operation | Unsecured fittings, poor mounting | Secure fittings, implement vibration damping, shield piping |

Grasping the shurflo pump exploded view enables users to locate malfunctioning components is crucial for effective resolution. Adhering to these guidelines ensures pump maintenance and reliable operation.

Final Thoughts

Comprehending the Shurflo Water Pump diagram is key for optimal Pump operation.

Utilized in various fields like RVs and agricultural spraying, efficient setup is crucial for dependable outcomes.

Understanding the parts in the diagram empowers users to install and maintain their systems effectively.

Installation Parts Supply stands as the premier source for all essential Shurflo Pump components and support, delivering extensive service along with vital instruments and elements. This ensures effective setups. Through correct installation practices and proper maintenance of elements such as the strainer, Pump durability and performance are improved.

This article arms users with the necessary knowledge to optimize Shurflo system performance. By taking advantage of Shurflo pumps and implementing installation tips, users are prepared to face any challenges with assurance.